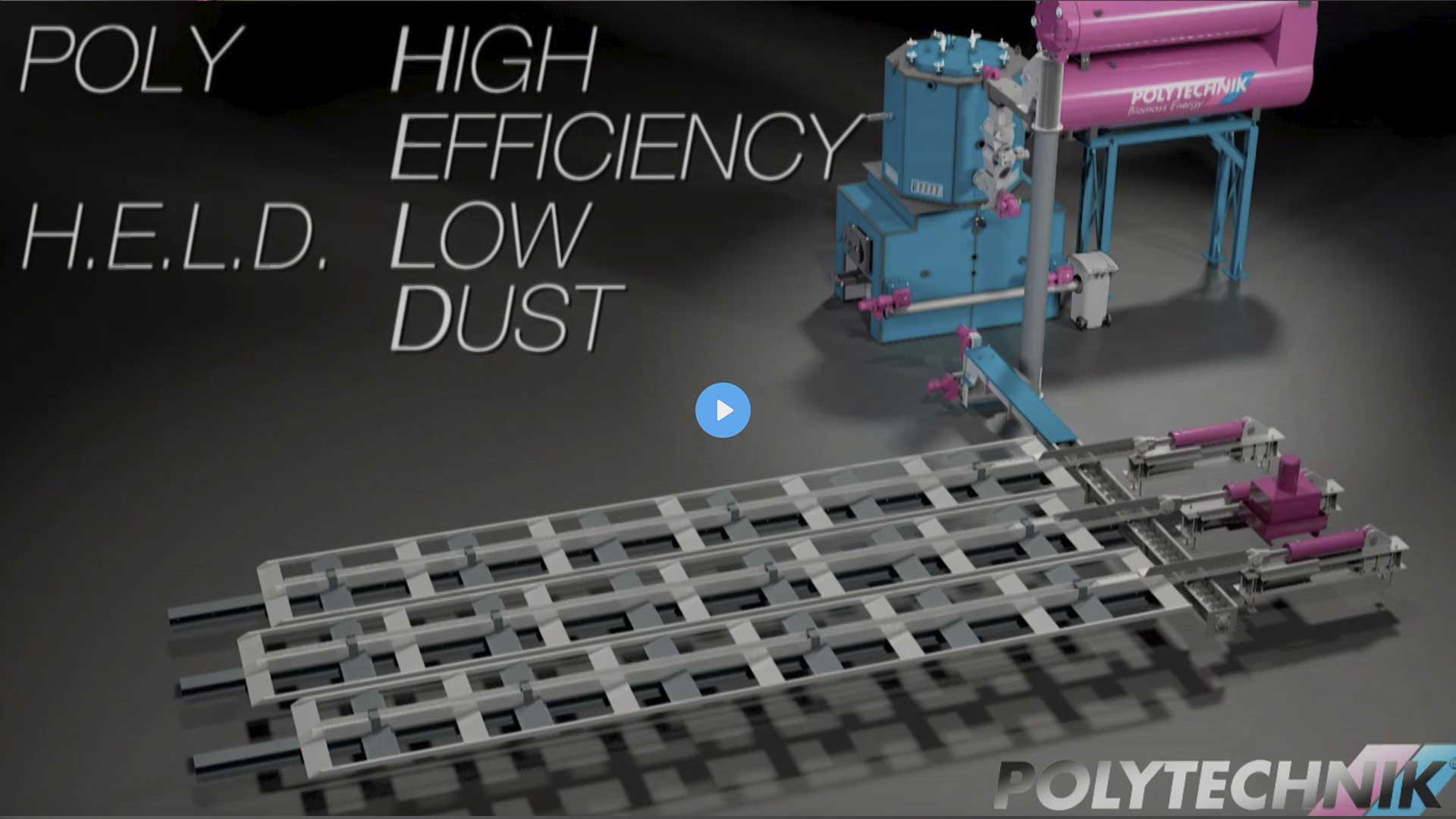

Poly-H.E.L.D.

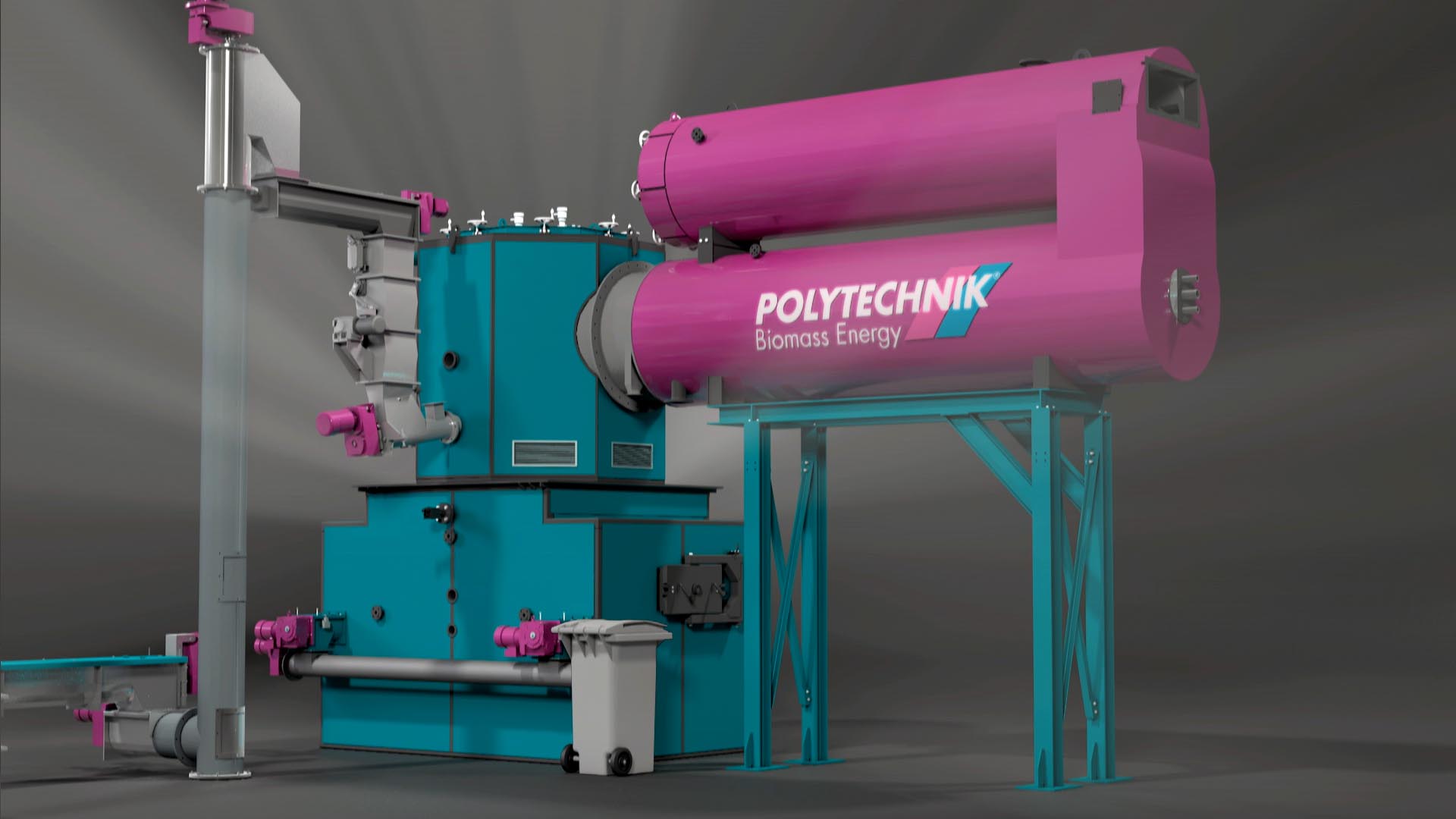

POLY H.E.L.D.® is the combustion technology of the future. The combustion system with extreme air staging, designed as fixed-bed type with counter-current, allows for a low-emission and efficient combustion of various fuels.

Low emission combustion

POLY H.E.L.D.® is the combustion technology of the future. The combustion system with extreme air staging, designed as fixed-bed type with counter-current, allows for a low-emission and efficient combustion of various fuels.

POLY H.E.L.D.® is the combustion technology of the future. The combustion system with extreme air staging, designed as fixed-bed type with counter-current, allows for a low-emission and efficient combustion of various fuels. Dust emissions for wood-based biomass remain lower than 20 mg/Nm3 at 11% O2. A value of below 10 mg/Nm3 can be reached with quality wood chips. Additionally, the POLY H.E.L.D. combustion technology is able to exploit high-ash fuels with relatively low ash melting points at low emissions. The system accomplishes these low emission values with primary measures and without an additional flue gas purification, which makes it a highly economical solution. As a unique design, this system achieved a 20-30% lower NOx emission (compared to conventional combustion plants) without secondary measures like SNCR or SCR.

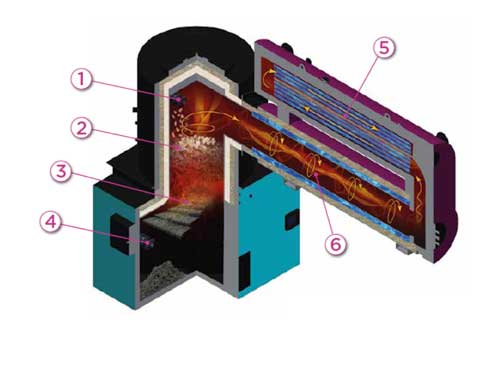

Fuel is supplied via a screw stoker (or other feed systems). Fuel height is controlled by a redundant measuring system. The plant is started automatically by a hot-air blower.

The grate is a conical grate, specifically developed for this technology by POLYTECHNIK. The new grate is mounted below the fixed bed and is cleaned from ashes simultaneously to the left and the right. In this process, the ash is discarded onto two screws on both ends of the grate and from there it is transported to another ash screw which transfers all of the ashes to a container. The grate frame is water-cooled.

The producer gas is combusted in a newly developed, multi-stage lean gas burner at low emissions with a slight air surplus and high efficiency. Subsequently, the flue gas flows through the heat exchanger and the energy can be used for various purposes: hot air, warm water, hot water, steam and/or thermal oil can be used as heat media.

OPERATING PRINCIPLES LOW EMISSION BURNER

- INLET

- FUEL BED

- GASIFIER GRATE

- ASH REMOVAL

- HEAT EXCHANGER

- SPECIAL LOW-NOx BURNER

Brochures

Contact us

You want to know more about our plants and your possibilities?

Call us at +43 2672 890-0, write an email to office@polytechnik.at or use the following contact form